Dry-air supply

Purpose

To

serve SCT/PIX/ TRT needs of

=

dry and filtered air with dew point <45 C as environmental gas at higher

flush rates

=

filtered compressed air for PIX/TRT

This

are the main supply filter stages which will be added to the existing

compressed air supply to provide the environmental gas at higher flush rate

(require about 5m3/h for SCT per test station).

This

may later be supplemented with dry N2 at much lower flow during during some

required tests (order of 500 l/h per test station in case of SCT)

The

distribution lines behind the filter will be stainless steel pipe work.

Filter stages

From

Richard:

The

choice of a 1" line will cater the pressure drop (25Mt) at a high flow

rate whilst not affecting the coordinate measuring machine stability.

The

1" compressed air line is protected by the following "Compair"

filter cartridges:

-

ref:CE 0087 A

(Grade

A - Pre-Filtration, Particle removal down to 25 microns)

-

ref:CE 0087 C

(Grade

C - High Efficiency Oil Free Protection Particles removal down to 0.01 micron

including water and oil aerosols, providing a maximum remaining oil aerosol

content of 0.01mg/m3 (0.01ppm) @ 21ľC)

-

ref:CE 0087 D

(Grade

D - Activated Carbon Filtration, removal of oil vapour and hydrocarbon odours

giving a maximum remaining oil content of <0.003mg/m3 (<0.003ppm)

(excluding methane)@ 21ľC)

The

pipe material should be TIG welded (inerted) stainless steel.

The

compressed air treated and delivered this way has no odourand no debris

avoiding the 'point of use' filtration.

The

maximum flow rate is quoted 4.8 m^3/min.

The

max. operating pressure is 16 Bars.

The

differential pressure is (100[A]+200[C]+70[D]) 370 mBar for a dew point of

-70°C.

This

is ideal for a 'free exhaust' in the room, the air pads of a CMM and moving

equipment on air cushions.

Spec sheets

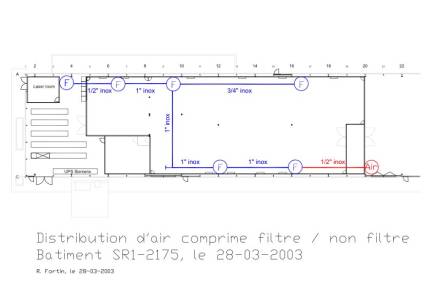

Distribution

Outlets are at the

following locations (supplied either from 1”, 3/4”, 1/2” pipes depending on

flow requirements) Piping is planned as stainless steel

This included a “cleaning

outlet”, outside the airlock, which is not filtered, to have compressed air

available for cleaning of dirty transport boxes/equipment/etc

Outlet will be placed close

to existing groups of Electricity/network outlet and can then be distributed

from their on locally to test setups