Minutes SR meeting 30/4/03 & Status of SR1 Building

(Click to open actions and presentations)

- Cooling system for SR1

- Status of SR1/ Followup on Actions

Present Actions:

IDAction

IDAction

Cooling system for SR1

The evaporative cooling system was discussed for SR1 . Information

for the TRT monophase will be collected by Mar and discussed at a later time.

A technical design for the evaporative cooling plant (cold and warm) is

ready (by Pierre/Marek based on Vic's concept). Open questions a summarized

below.

Pierre & Marek will circulate the technical design when updated.

1.) Cold system (C3F8)

It is not decided which compressor for the cold C3F8 system will be used.

A new compressor type has some promising advantages (in particlar for the

later final system): cheaper, smaller, more capacity.

Pierre will try to get this compressor for tests in the next 2 weeks and

then test it until end June. If it is found to be ok, it will be used right

away for the SR1 evap. cooling system.

If it is not usable we will proceed with the "old" compressor type (3mo

delivery time ARO)

2.) Warm system

Based on recent information , it will be very expensive (impossible?) to

get C4F10 at CERN.

Pierre/Migel will look into using other coolant for the warm system (C5F12,

etc...). The choice of the coolant will most likely not change the layout/components

in the warm system.

It was decided that the warm and cold system have to be usable independently,i.e.

run one test setup warm while another runs cold. (ie. double piping along

main distribution up to mainfold on the wall.

Marco propose to have only one system based on C3F8 and run it at higher

pressure for a warm operation (7 bar?). Advantages are only one system instead

of 2, no switch over of collants in the detector required.

Marco will check with SCT/PIX project engineers the feasibility of this

proposal

3.) Manifolds/Pressure regulators

The manifolds in the assembly area (8 circuits PIX, 5 circuits SCT) are

planned as manuel values (check safety).

The 44 circuits in the assembly area need to be discussed. Options are :

manual values, pneumatic values, electrical values for pressure regulation

(Steinar/Marco/Heinz with Pierre/Marek). Issues to address are: control system

complexity, safety of operation, costs. This will be followed up next week.

All values need to be warm.

All circuits are now 1 inlet on 1 outlet. The split into different inlet

capilaries (2 on 1 SCT barrel, 1/2/3 on 1 SCT fwd) will be done on the detector

level!

Heinz will check for work shop possbilities for the manifold construction.

4.) Other

The barak for the cooling plant in the back of SR1 will be constructed once

the plane dimensions and installation requirements are clear.

The location for the control rack needs to be defined.

During installation the SR1 door close to the plant can be used.

Dummy loads: we will get the dummy load, which is currently in Oxford back

during the summer for testing. BUT this dummy load is too small for a full

compressor tests, so we will require additional dummy load(s).

5.) Time scale

Marek/Pierre will now prepare an inventory list of all items so that we

can proceed with the orders for all undisputed items.

An approximate time scale is

- make inventory list : now - mid May

- check for warm C3F8 system / replacement of C4F10: now - mid May

- order/delivery of first plant components: mid May-end June

- test new compressor: now to end June

- assembly of cooling plant : beg July to end Aug

- start commissioning/testing in lab : Sep.

- pipework in SR1: Aug-Sept

- construction of manifold: July-Sept.

open issues:

- control of pressure regulators

- cooling DCS to be defined when regulation is clear

2.) Status of SR1 - followup on actions

1.) Electricity installation

finished

2.) Network installation

finished

3.) Phone lines

3 lines installed, 4th (next to laser room) remains

4.) UPS

UPS are installed and connected to main electricity.

Siemens will come on 7/8 May for maintanence checks and verify the UPS operation

of both UPSs. They are planned to be operational by 15/5

5.) Dry air/ Compressed air

Quotes of piping received and ordered. Side visit with installation company

was done on Tuesday. Piping will be stainless steel pipes mounted next to

cable trays in clean room. Installation will start approx. 20/5 (to be confirmed).

This will provide clean compressed air with a dew point of -10C at different

places.

Additional air dryers (for dew point of -40 to -45C) will be installed

directly at point of use. Noise tests on those dryers are currently being

done on one of them which is available in Bat 161.

6.) Cable trays

Order was received by company. Installation is planned to start on 12/5.

It will take about 2 weeks in the clean room + 1 wk in rack area. First step

of installation is the installation of the cable tray support beams every

3m in the clean room. These are all trays in SR1 except trays from TA wall

to service support on TA platform.

7.) Service support for test cables in TA

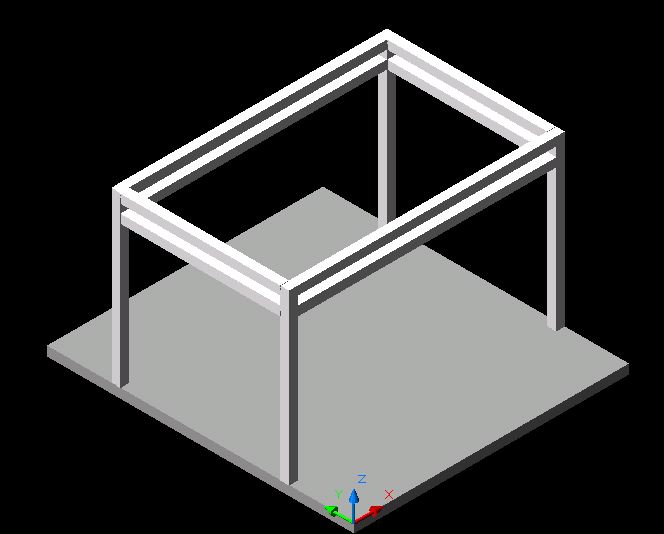

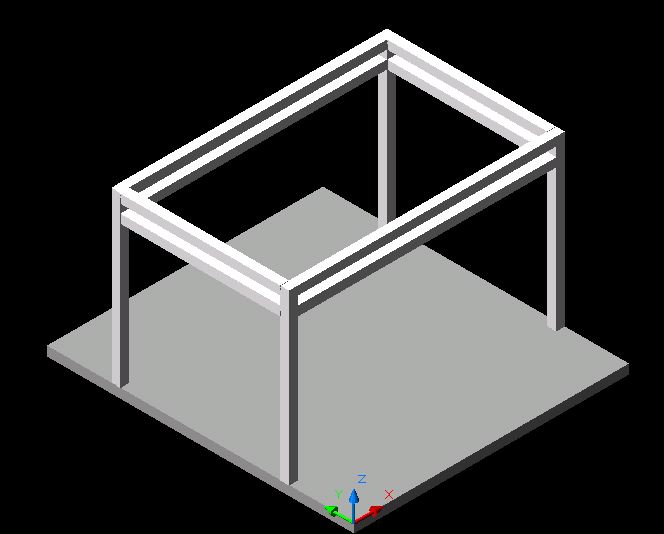

It was decided to proceed with the drawings for a "table-like" service

support structure on the platform in the test area. We plan to span the full

width of the platform in order to have maximum flexibility for tests/integration

work in this area.

At structure is expected to be about 6.2m wide, 4m long (to allow side-ways

insertion/extraction of the ID trolley) and approximately 3.8m high. The clean

volume is approximately 3.6m (length) x 5.8m (width) x 3.2m (height). Richard

will proceed with the drawings for this structure. Manpower is most likely

available for its contruction by mid May.

Sequence:

- confirm dimensions (when drawing is ready)

- sign off by TIS for statics/safety

- order of material (beams)

A sketch of the support to illustrate its layout is below (The shown platform

corresponds to the dimensions of the TA platform):

8.) Emergency smoke extraction

finished. Official reception is on 11/5

9.) DCS

The prepareparation of the CIC DCS progresses well. The necessary hardware

has been order. The distribution and cabling is described below (Fernando)

SR_CANbus_layout

SR_CANbus_layout

The first version of the SCT power supply DCS has been installed in Oxford

before easter (Ewa,Heidi,Pamela). Oxford has now one full SCT PS crate available

for tests. The DCS work on SCT PS continues now at Bat 161. A first test version

for the PS DCS (1 crate controlled through the final crate controller, OPC,

PVSS insterface) is expected to be ready by mid May.

10.) Space allocation

Below is a _proposed_ space allocation for

- SCT/TRT system tests

- ITT for PIX integration tests

The ITT tests require a space of 12 x 3 m and it is proposed to use the

lower part of the SCT area in order to keep the central moving corridor clear.

The space is required end this year, early next year. Eric will confirm if

this is possible wrt 4-barrel assembly tool preparation/setup (which is planned

for this area in 2004)

SR1_FloorPlan010503

SR1_FloorPlan010503

11.) Racks

All cooling pipes for water cooled racks have been stripped. The installation

of rack infrastructure (electrical distribution of rack, mounting of cooling

pipes, heat exchangers etc) started and will last for two weeks now. (Per,

Arvid, Richard). The rack cooling system (installed except flex. connection

to racks) will be commissioned by ST as our rack work is finished.

12.) Immediate time plan SR1

7/8 May: UPS check by SIemens

12 May: Start cable tray installation

approx 20 May: pipework for dry air system

approx 25 May: start cleaning of cleam room/laser room (order signed list

week)

now-14 May: rack work (commission of cooling by ST/safety checks after that)

June 1: start of moving to SR

IDAction

IDAction