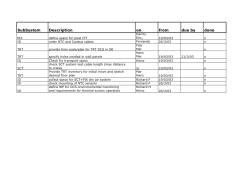

Minutes 26/3/03 and Status SR1

Present Action

list

For your attention

There will be a clean room course at Cern next week and people

planning to work in the clean room are encouraged to attend it.

ItŐs free and reasonable in length

1.) General/Global SR1 DCS (Helfried/Richard)

DCS group wants to use the ID parts of the DCS to test the

global DCS, will setup infrastructure for global system. DCS PCs are

ordered/available.

Slava currently helps with OPC server expertise, later

possibly with the cooling system.

Database handling will come in a second stage.

It was discussed if we should merge the environmental

monitoring for thermal screen LCS and cooling LCS as they are to be very

closely integrated anyway. Steinar/Richard/Heinz prepare WP description for

cooling/thermal screen DCS.

User interface for LCS is part of the group making the LCS DCS.

DCS group can provide samples.

Need to list which LCS station is on which level (to be

followed up by Richard H /Heinz)

Software interlocks and interrupts from substations go

through global system.

2.) CIC (SR1 plant & infrastructure monitoring) (Fernando,

Balasz)

at the moment includes: Rack monitoring, (monitoring only,

no interrupt), Temperature and humidity monitoring in the different SD1 room.

This is in progress now.

Should include 1 pressure sensor in clean room.

For later: monitoring for venilation system,UPS etc....

Fixation of NTC sensors in racks needs to be worked out

(RIchard to ckeck)

The first version should be avilable in 4-6 weeks for

trials

3.) SCT power supplies DCS (Ewa, Pamela, Heidi)

in progress now. Based of DCS from SCT LVS for power

supplies to ELMB.

Dedicated special ELMB software is being developed for the

crate controller. The LCS part will follow DCS standards.

Present status:

-

we can send commands to the ELMB and read back from the buffer

-

we can send simple control messages

-

we control and monitor globally the HV and LV channels as well as

individually. For the control we are

using as a guideline your document

describing the run state transitions. Heidi

has prepared a table that will

be sent to you soon together with an

update of the parameter list

discussed already with Pamela and Ewa.

-

we are starting to work on configuration of the crate and we have decided to

base it on an ASCII file for the moment

and in the next future on XML files

that could be easily imported in a

database.

-

Next we will start to deal with error messages.

-

Of course next week we will try all of this on real HV/LV modules.

-

Our project is a distributed project is made following the JCOP framework

rules, thanks to the close contact we

keep with Fernando.

-

We are also in contact with Abdel, next week he will be at CERN and we

hope to test some DDC commands at this

stage

Datastorage

through PVSS archieve, DCS group will explore possibility to use Oracle.

This should be done together with CIC data storage.

4.) TRT DCS (presented by Fido)

mainly effort by Krakow group now. The first part of the

TRT DCS for SR1 will also be power supplies (Hv). Fido will prepare timeplane

with Krakow group next week for DCS in SR1.

see attached pdf file on TRT SR1

DCS.

5.) Present SR1 Status

a.)

Electricity/Network

Installation of electricity and network progresses well. All

AC outlet boxes are installed and most are cabled

All network outlet boxes are installed and cabling started

b.)

Control

Room

The airlock from control room to assembly area is

installed. Also the window from control room to test area is installed. The airlock

still needs to be painted.

The network outlets in the control room have been slightly

group for simpler installation (same number as before but grouped to one group

of outlets on each wall)

We will order 4 small local UPSs to serve some of the

PC located in the control room.

c.)

Clean

Room

Two roof panels in the airlock have been replaced by

Schulthess. The installation drawings for the cable trays are ready but we

still wait for the quote.

For AC local distribution we will order five standard

distribution rails in to be fed by the 220V/25A outlets in the assembly and

test area. They will be wall mounted.

d.)

Rack

area

The refurbishing of the racks in the rack area has started

by Per & Richard this week. This will include

= adjustment of ventilation side panels to fit our

specified rack layout and rack distribution

= cleaning and check of water cooling plumbing in racks

= mounting and connection of heat exchangers in water

cooled racks

= preparation for rack water cooling commissioning by ST

(commissioning of pumps, heat exchangers, control)

e.)

Access

control

We received the plan for the access control.

Access control (card readers) will be installed on the

entrance door to the control room (from the rack area) and on the main clean

room entrance through the airlock. They will be connected to Ethernet and

access check is provided by a database. The quote and installation plan is

available.

The mode of operation is

= access with your Cern card

= access is given on an individual basis for a specific

period of time.

= the access database is updated 4 times daily

6.) Follow ups: Supply of dry air and clean compressed

air

See page on SR1 dry air

supply